Electronic microporous leak detector for ampoule injection

Main Application

It is mainly used for leak detection of ampoules, vials and oral liquid bottles. Including the detection of cracks in the bottle's pores, sealing part, bottle body, bottle bottom, etc.

Working principle

The bottle feeding conveyor belt sends the containers to be inspected to the bottle feeding wheel for equidistant separation, and then sends the containers to the conveying screw via the bottle feeding twisting channel for turning over. The container reaches the different inspection stations in a horizontal state after being turned by 90°. The detection consists of multiple stations, which can detect different positions according to user requirements, and finally pass the reject mechanism to automatically separate qualified and unqualified products.

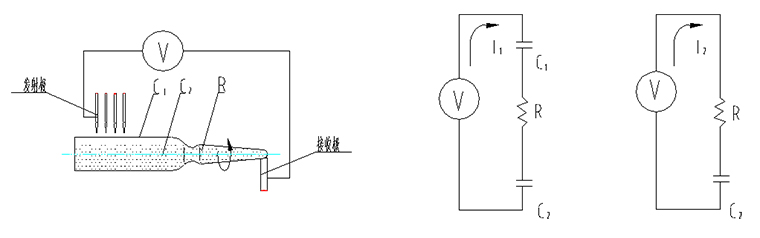

Detection principle

V is the high-frequency and high-voltage detection power supply, and the two ends are connected to the emitter and the receiver respectively. C1 and C2 are the capacitance values between the electrode and the solution (due to the partition of the insulating bottle wall, the electrode cannot be in contact with the solution, so capacitance is generated), R is the resistance value of the solution. When the container does not leak, an induced micro current I1 is generated. When the container leaks, the capacitance between the bottle wall and the electrode disappears, the capacitive reactance generated by the capacitor is zero, and the loop generates a larger micro current I2. By comparing the magnitude of the micro current, it can be judged whether the container is leaking.

Main Features

It can be produced on a stand-alone machine or linked with the production line to automatically inspect the inspected containers one by one online

Can detect ultra-fine cracks and micro-holes that cannot be detected by traditional methods

Due to the low energy and short time loaded on the container to be inspected, qualified drugs are in an insulated state when they pass the inspection area, and the detection voltage has no side effects on the inner liquid of the drug, realizing non-destructive inspection of the container and the drug

There is no direct contact between the detection electrode and the medicine, so it will not pollute the medicine

A piece of equipment can be adapted to the production of multiple specifications and the production of multiple containers by changing the mold. Containers such as ampoules, antibiotic bottles, oral liquid bottles, etc. can be produced on one device, which improves the utilization rate of the device

Human-machine friendly touch screen interface, with powerful control, display, data collection and printing functions

Provide a full set of verification standards that meet GMP requirements

At present, the leak detection series products have obtained a number of patents (see "Patented Technology" of "Manufacturing and Quality" on the company website)

CONTACT INFORMATION

OFFICIAL ACCOUNTS